Bevel Gearbox for COMILL & DELUMPER

Bevel Gearboxes for speeds 1500 Upto 2500 RPM

-

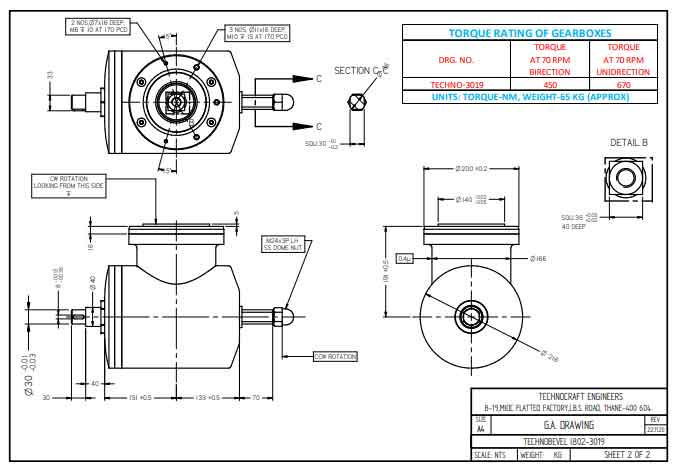

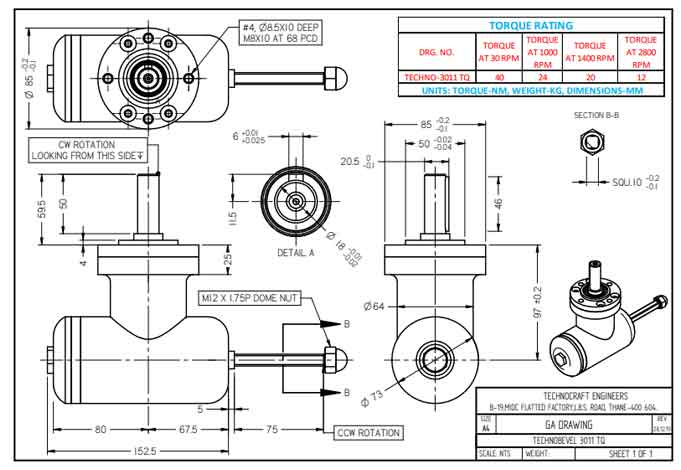

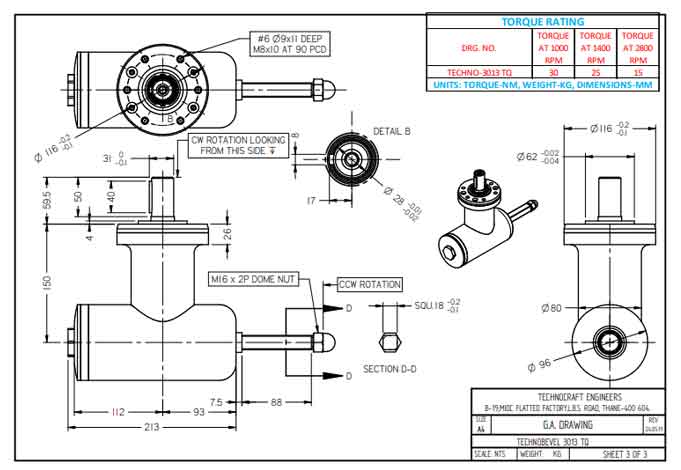

Various Models developed so far as follows

- A} TECHNOCRAFT 1014 For 1 HP

- B} TECHNOCRAFT 3013 TQ UPTO 5 HP

- C} TECHNOCRAFT 3020 TQ UPTO HP

For High speed applications we use Ground Spiral Bevel Gears

Specification

• Precision grade JIS B 1704: 1978 grade 1

• Pressure angle 20°

• Helix angle 35°

• Tooth hardness 55 - 60HRC

• Gear ratio 1

• Material SCM415 SCM415 Steel is a high quality Quenched and Tempered Alloy Structural steel, It belong to the high quality medium carbon,

• Oil Quenched & Tempered Hardenss is 28-34 HRc. SCM415 Annealing delivery hardenss less than 250HB.

The Requirements for CO MILL summarised as follows:

1.Right Angle Bevel Gearbox 1:1

2.Power of the connected Motor : Operating RPM : In the range of 500 RPM to 2000 RPM

3.Material of Construction : All the external surfaces Fabricated out of SS - 316L grade with TC

4.External shape : to be inline with GMP guidelines (e.g there should not be any external crevices. Should be smooth…so that the product, which is pharmaceutical powder, easily slides over and falls down)

5.All external surfaces should be washable and sterilizable (by steam)

6.Exposed plastic/rubber surfaces (for example the seals) of food grade/FDA approved. Viton seals and Food quality grease used.

7.Self-sufficient in terms of lifetime lubrication

8.No oil spills/leakages

SALIENT FEATURES:

1)HOUSING, SHAFTS MATERIAL SS 316-L AS PER GMP GUIDELINES

2)APPROPRIATE AND BEST QUALITY BEARINGS

3)HIGH PRECISION SPIRAL BEVEL GEARS WITH TEETH GROUND IMPORTED FROM JAPAN

ON ACCOUNT OF ACCURACY AND SPECIAL RAW MATERIAL SMALLER SIZE ENABLES COMPACT GEARBOX AND SMOOTH & NOISELESS OPERATION.

4)VITON SEALS USED

5)FOOD QUALITY GREASE USED

DELUMPER

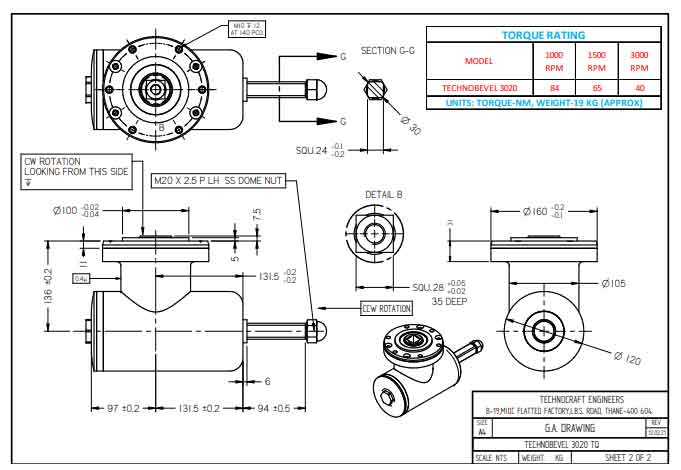

MODEL: TECHNOCRAFT 3020

The Bevel Gearbox is used for changing the orientation of rotation by 90 Degrees.

The output is derived from combination of Motor and Worm Gearbox.

Here speed is low however Torque to be transmitted is high.

The Bevel Gearbox 1:1

The Requirement for DELUMPER is summarised as follows:

1.Right Angle Bevel Gearbox 1:1

2.Operating RPM : In the range of 30-60 RPM. Torque 500 NM TO 1000 NM.

3.Material of Construction : All the external surfaces Fabricated out of SS - 316L grade with TC

4.External shape : to be inline with GMP guidelines (e.g there should not be any external crevices. Should be smooth…so

that the product, which is pharmaceutical powder, easily slides over and falls down)

5.All external surfaces should be washable and sterilizable (by steam)

6.Exposed plastic/rubber surfaces (for example the seals) of food grade/FDA approved. Viton seals and Food quality grease used.

7.Self-sufficient in terms of lifetime lubrication

8.No oil spills/leakages