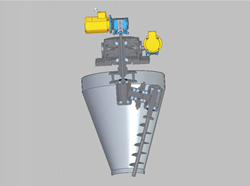

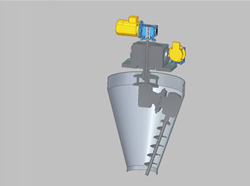

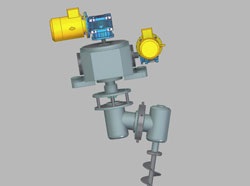

Complete Drive For Nauta Mixer

REQUIREMENT:

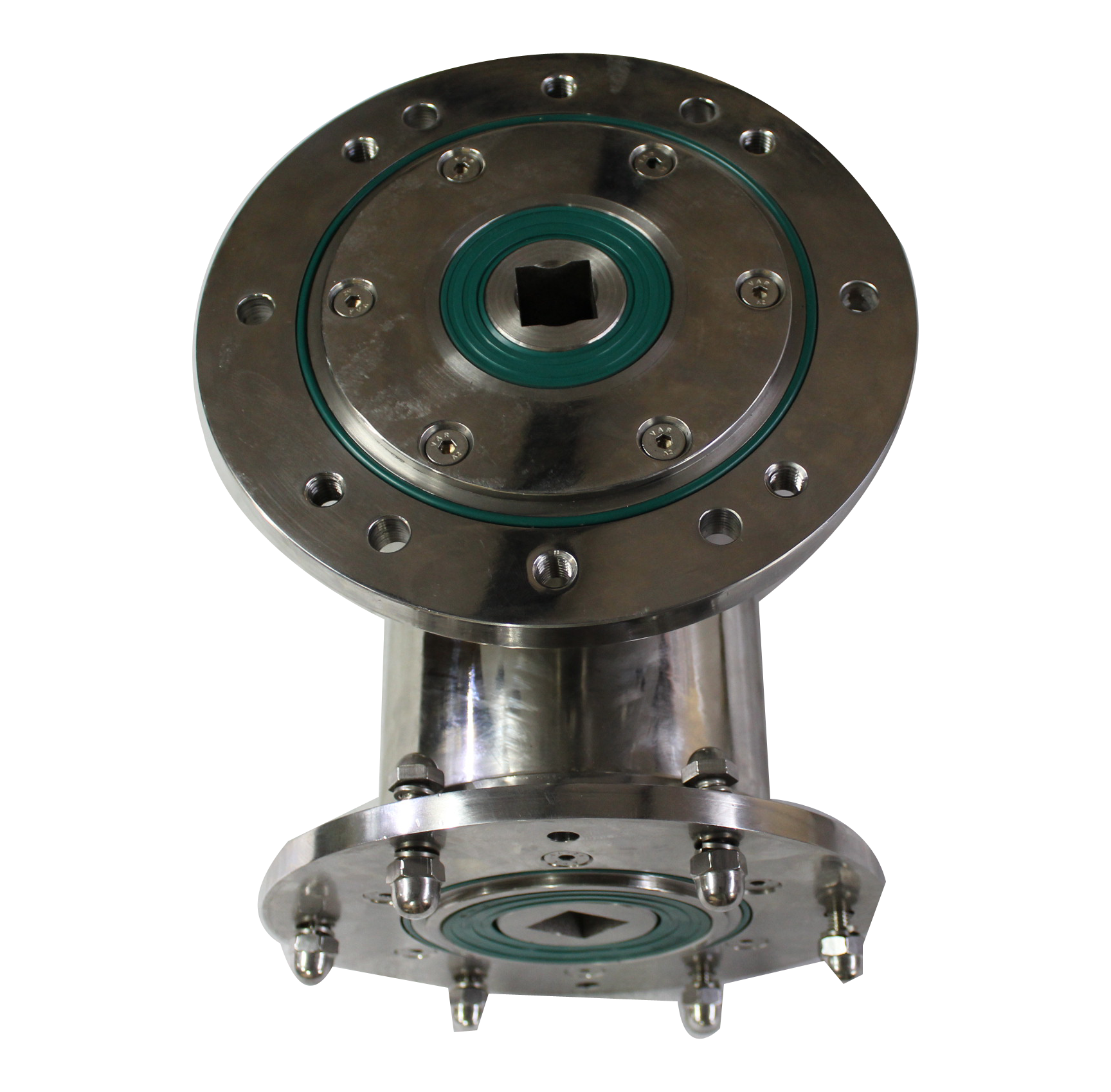

Two separate drives

A} ARM MOVEMENT 2000 NM at 1 RPM

This will rotate entire Arm Assembly

B} SCREW MOVEMENT 200 NM at 60 RPM

Both above Units fitted inside conical shell as per requirement.

The diameter of the Conical Tank is 900 mm with Cone Apex angle 34°.

SALIENT FEATURES:

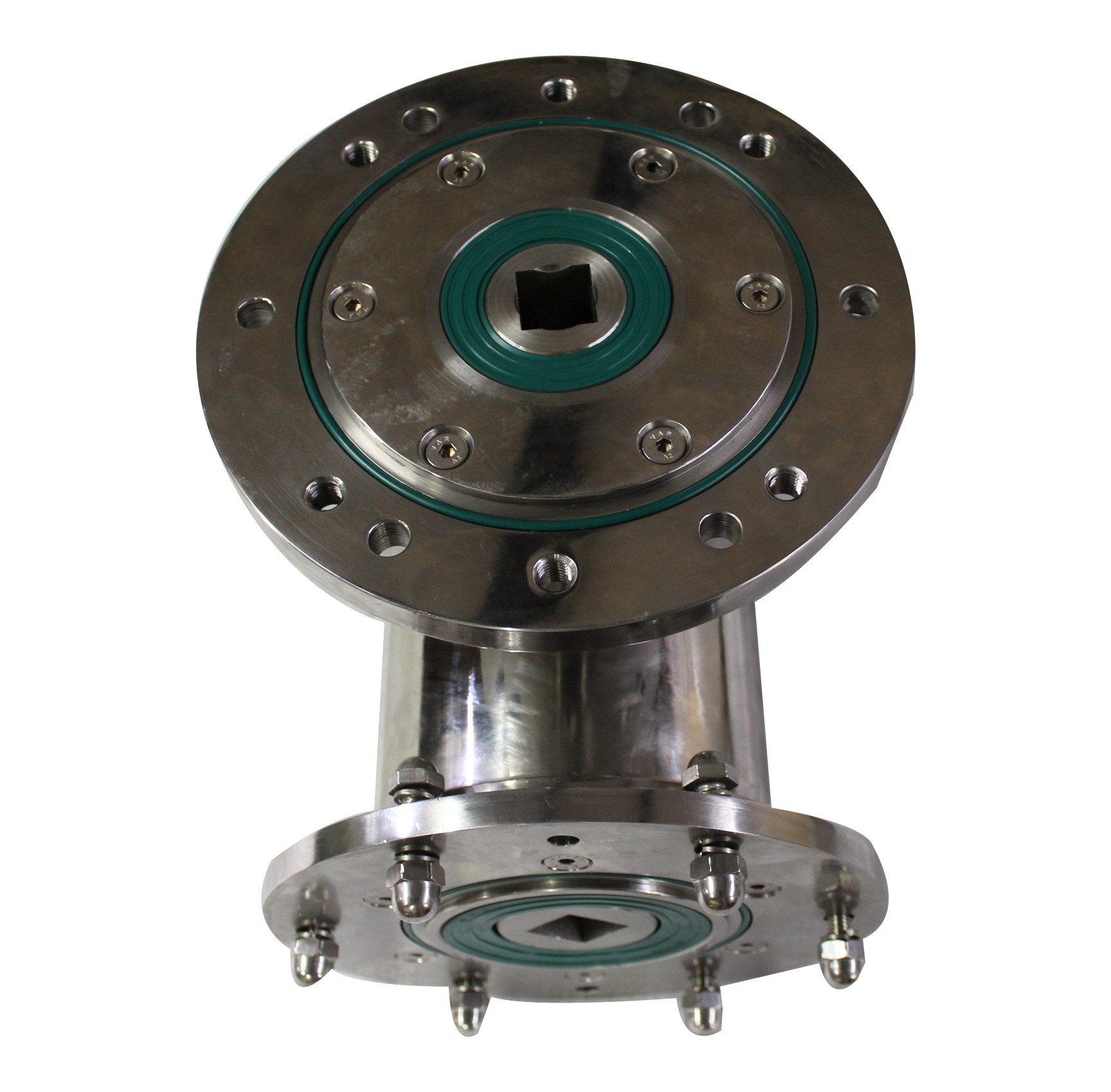

A} ARM MOVEMENT:

Input 0.75KW 4P AC Motor with W-63 Model Gearbox Ratio 25, Output Torque 100 NM at 60 RPM.

We have designed Special Worm Gearbox with following Features

a)Ratio 60 Output Torque 2000 NM at 1 RPM.

b)Bearings at output shaft designed considering additional axial Load 1000 N

c)Output Shaft having Bore around 35 MM and another Shaft dia 28 will Rotate freely from Inside at 60 RPM which will be Input to Bevel Gearbox situated Inside the shell and will rotate Screw at 60 RPM

d)The Gearbox will be situated just above the Centre of the Shell from outside.

B} SCREW MOVEMENT:

Input 1.5 KW 4P AC Motor with W-75 Model Gearbox Ratio 25, Output Torque 200NM at 60 RPM

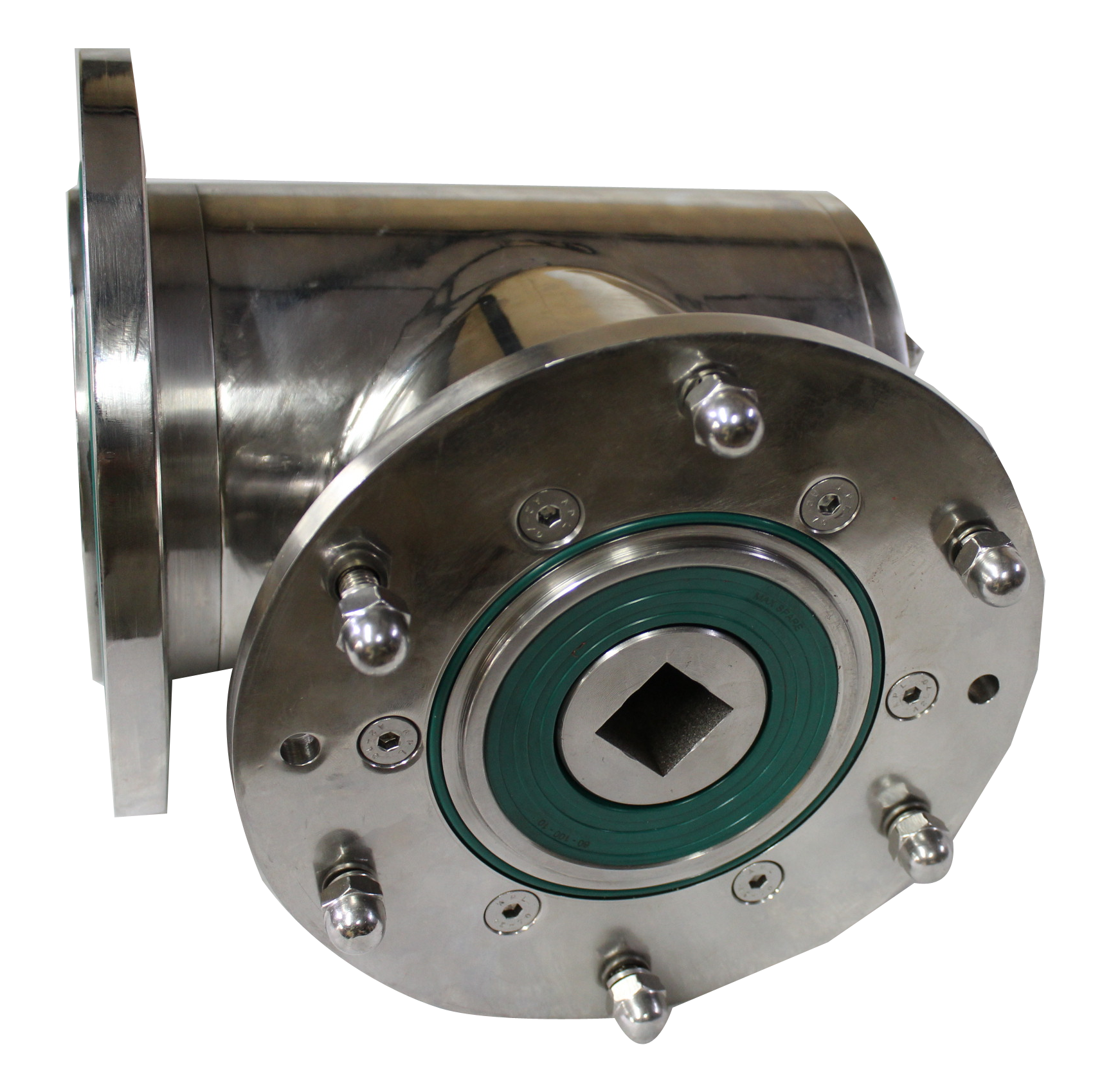

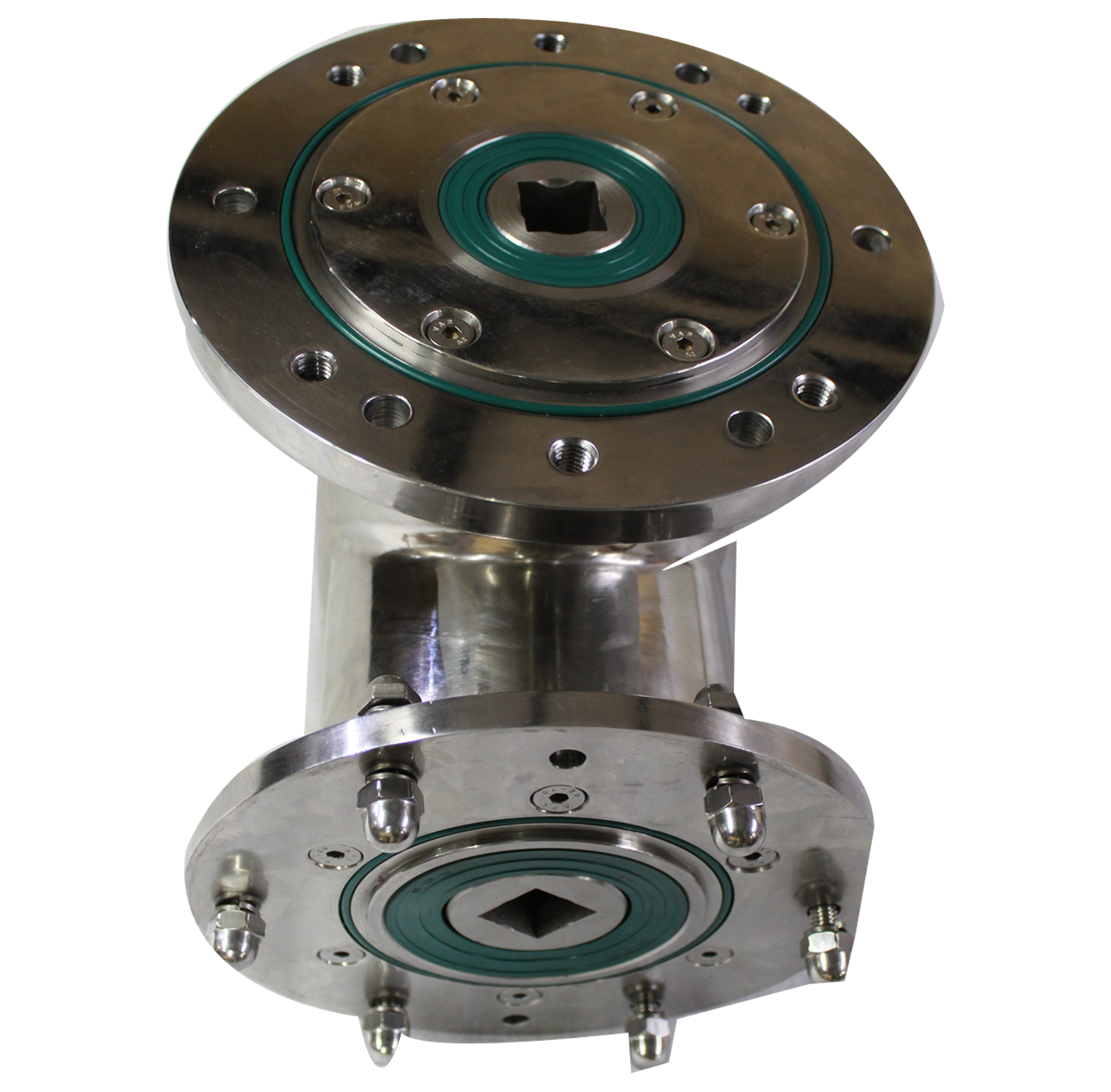

I ) FIRST STAGE BEVEL GEARBOX OUTPUT SHAFT 73 DEG

a ) Ratio 1:1

b ) The Gearbox mounted with a flange coupled with Output shaft of Worm Gearbox (ARM MOVEMENT)

c) Gearbox Input From Drive mentioned above by a shaft coupled with W-75

d )Output Shaft at 73 Degree to suit Cone angle 34 Deg.

e ) Output Shaft Squ. – 30

f ) Gearbox Housing, All Body Parts and Shafts SS-316 L

g) St. Bevel Gears Material SAE 8620, Teeth cut on Bevel Gear Generator,

Case Hardened and concentrically ground.

h) Gearbox as per GMP guideline

i ) Food Quality Grease, Viton Seal

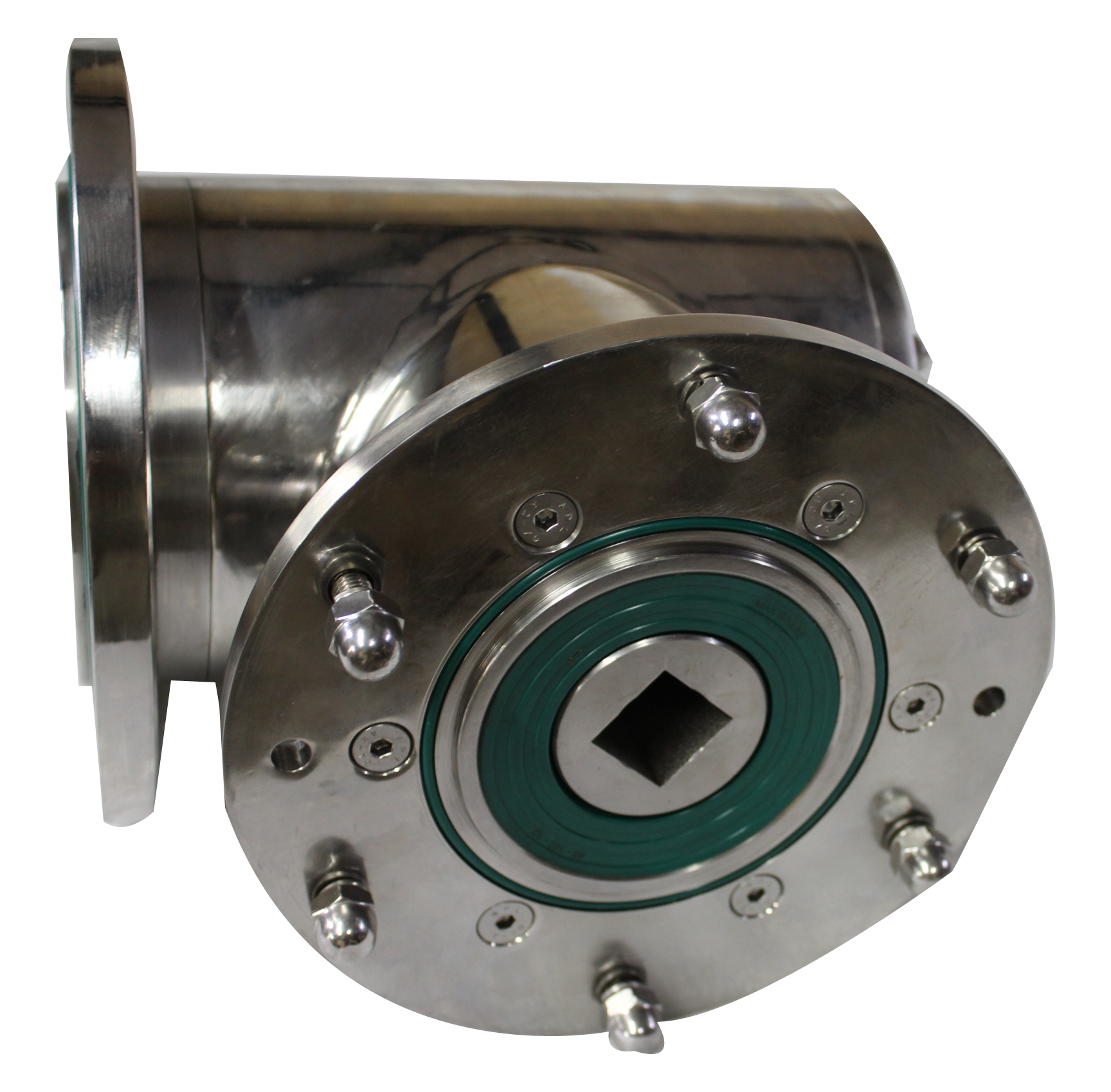

II)SECOND STAGE BEVEL GEARBOX OUTPUT SHAFT 90 DEG.

a ) Ratio 1:1

b )The Gearbox fitted with Gearbox-I (First Stage) by means of a threaded Coupling

c ) Hollow Input Squ. – 30 to match FIRST STAGE Gearbox.

d )Output Shaft having suitable Flange to connect SCREW

e ) St. Bevel Gears Material SAE 8620, Teeth cut on Bevel Gear Generator, Case Hardened and cylindrically ground.

f ) Gearbox Housing, All Body Parts and Shafts SS-316 L

g ) Gearbox as per GMP guideline

h ) Food Quality Grease, Viton Seal

FOR ARM MOVEMENT

0.55KW 4P AC Motor with 25 Ratio W-50 Model Gearbox (73 NM) i=25

FOR SCREW MOVEMENT

1.5 KW 4P AC Motor with 25 Ratio w-75 Gearbox (200NM) i=25