Some Other Projects Handled

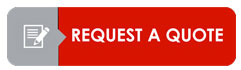

We have designed manufactured and supplied Special Purpose Motorized Lift Mechanisms for nuclear material handling purpose inside Glove Box.

SALIENT FEATURES:

1} Machine using world class technology Linear Guides and Ground Trapezoidal Lead Screw M20x4P (International Brand) Hiwin Make (Model 15CC) Rails and L.M. Guides Two Rails and Four Guides.

Imported Lead Screw Trapezoidal Threads M20x4P, Material EN-8

Electro less Nickel Plating (ENP)

2} Minimum Friction and smooth operation with High efficiency.

3} Requirement of Power - 90 Watts,230 VAC, Single Phase,

1440/140 RPM, Flange Mounted Worm Geared Motor.

Weight for movement considered 50 Kg. Linear Speed – 0.6 Mtrs/Min.

4}Guide Base Frame Material SS-304

5} Lift – 330mm Upward Downward Movement

Positional Accuracy +/- 0.2

6} Other than Lead Screw and Rails entire components in SS-304

7} SS Sheet Metal Covers provided to enclose the mechanism

8} Sturdy Design and construction. Easy to dismantle and re assemble

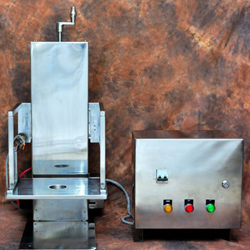

We have designed complete Lift Mechanism for TABLET DISSOLUTION TEST APARATUS

We have used High Precision Rails and LM Guides and Imported Lead Screw for smooth operation.

We have been supplying to Leading Manufacturer with all accessories like STIRRER HOUSING, TOP HOOD, TIMING PULLEYS. The drive is 90 Watts 960/100 RPM AC Geared Motor manufactured by us.

Vertical column fitted with Rails eliminates all complicated components for Linear Movement.

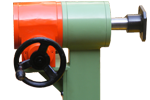

2. Engine Overhauling Stand

Special Purpose Gear Box with Self Locking Characteristic for Engine Mounting Trolley

• This is a Hand operated Gear Box, with extended shaft.

• Automobile engine to be overhauled is mounted on the shaft by means of special adapters fitted either at Bell Housing or at Exhaust manifold.

• This facilitates easy assembly of parts on the engine body.

• Used at automobile dealers/ Service stations.

• End User: Fiat India Ltd. TATA MOTORS, MAHINDRA & MAHINDRA LTD.

• This is a Service Tool

• Besides we have also developed various Service Tools for the similar applications.

3 Gearbox and Drive for Welding Automation

We have supplied special purpose welding automation projects for Larsen and Toubro Ltd Powai, Mumbai works. We design Gearbox with Hollow Output shaft so that the welding apparatus (like Torch, welding Gun etc) can be inserted through the shaft and welding / grinding and allied operations are carried out synchronously.

One such project has been elaborated as follows,

This was a first of its kind activity in the world executed for L&T and in turn for the final customer NPCIL, on their KGS 3 Atomic Reactor at

Kaiga – Karnataka state

The task involved was to synchronize the motion for the grinding and welding operations on a Weld joint in a live Atomic Reactor.

The critical part of the activity was to execute grinding and welding in an ID of 145 mm from a distance of 2.5 meters making use of cameras for vision. The entire design of drive system, (consisting of planetary gear box, DC Motors, AC servo Motors & all related controllers etc.) manufacturing of the system components & trials was the scope taken up and executed successfully..

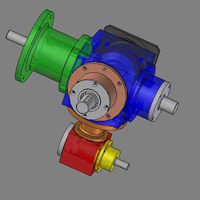

Bevel Gearboxes with 4 Output shaft

• This is a typical application where in synchronized motion transfer is required to operate different units simultaneously in a blister packing machine.

• The concept was explained to us and we have engineered the solution.

• The drive is 3HP servo motor with a worm gearbox reduction.

• Teeth generated Bevel Gears with high accuracy and case hardened are used.

• Least amount of backlash has been maintained.

• There are One Input and 3 Output shafts in one plane and besides another shaft id extended downwards to give one more output.

• SKF or equivalent make ball bearings are used.

• Lubrication is appropriate grade Grease to avoid leakages

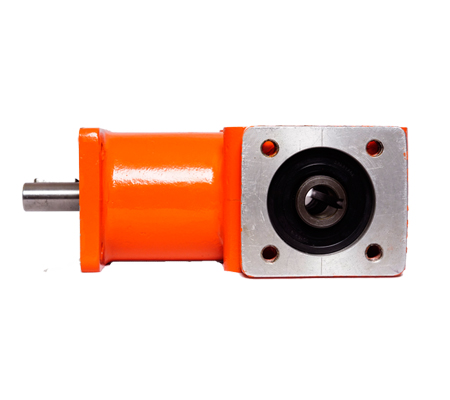

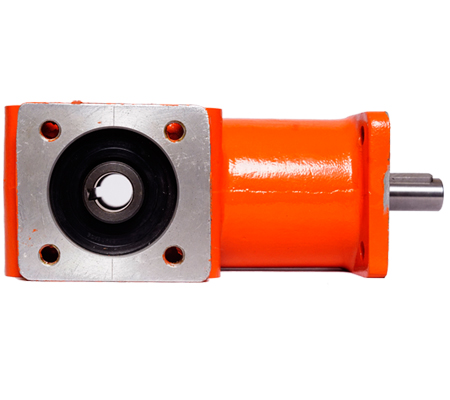

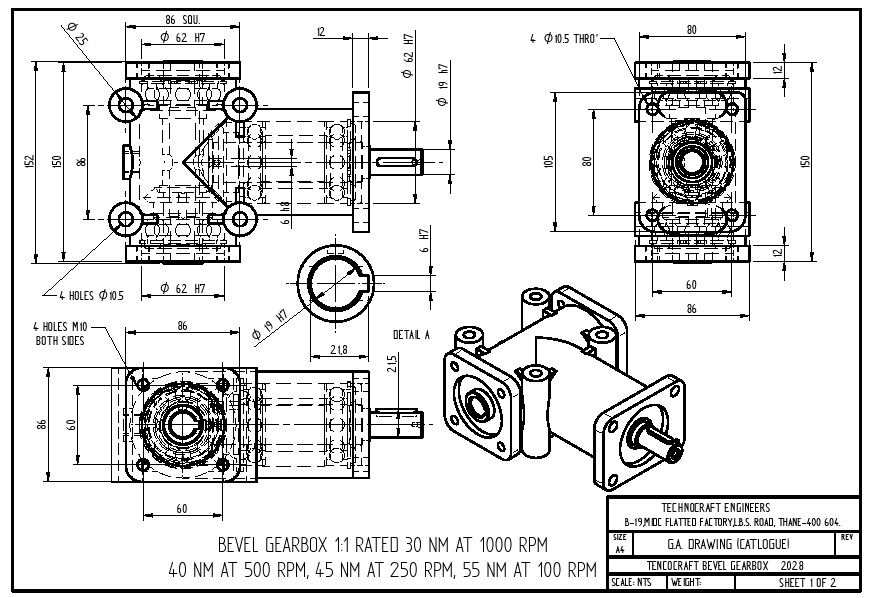

Bevel Gearbox Techno-2028

RATIO – 1:1RATED TORQUE:

30 NM AT 1000 RPM

40 NM AT 500 RPM.

45 NM AT 250 RPM

ALUMINIUM GEARBOX HOUSING

SMOOTH TRANSMISSION

MULTIPLE MOUNTING FACILITY

CLOCKWISE TO ANTICLOCKWISE AND CLOCKWISE TO CLOCKWISE DIRECTION FACITLITATED JUST BY REVERSAL OF MOUNTING FACE