Welding Automation

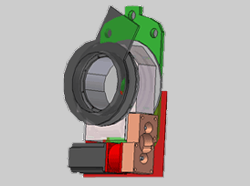

We have supplied special purpose welding automation projects for Larsen and Toubro Ltd Powai, Mumbai works. We design Gearbox with Hollow Output shaft so that the welding apparatus (like Torch, welding Gun etc) can be inserted through the shaft and welding / grinding and allied operations are carried out synchronously.

One such project has been elaborated as follows,

-

This was a first of its kind activity in the world executed for L&T and in turn for the final customer NPCIL, on their KGS 3 Atomic Reactor at

Kaiga – Karnataka state

-

The task involved was to synchronize the motion for the grinding and welding operations on a Weld joint in a live Atomic Reactor.

The critical part of the activity was to execute grinding and welding in an ID of 145 mm from a distance of 2.5 meters making use of cameras for vision. The entire design of drive system, (consisting of planetary gear box, DC Motors, AC servo Motors & all related controllers etc.) manufacturing of the system components & trials was the scope taken up and executed successfully..

We are using High Precision Spiral Bevel Gears with Ground Teeth, imported from Japan.

Specifications as follows,

Precision grade JIS B 1704 : 1978 grade 1

Gear teeth Gleason

Pressure angle 20°

Helix angle 35°

Material SCM415

Heat treatment Carburizing

Tooth hardness 55 60HRC

Gear ratio 1

Screw offset (L) Half of hub width (H)

The Requirements for CO MILL summarised as follows:

1.Right Angle Bevel Gearbox 1:1

2.Power of the connected Motor : Operating RPM : In the range of 500 RPM to 2000 RPM

3.Material of Construction : All the external surfaces Fabricated out of SS - 316L grade with TC

4.External shape : to be inline with GMP guidelines (e.g there should not be any external crevices. Should be smooth…so that the product, which is pharmaceutical powder, easily slides over and falls down)

5.All external surfaces should be washable and sterilizable (by steam)

6.Exposed plastic/rubber surfaces (for example the seals) of food grade/FDA approved. Viton seals and Food quality grease used.

7.Self-sufficient in terms of lifetime lubrication

8.No oil spills/leakages

SALIENT FEATURES:

1)HOUSING, SHAFTS MATERIAL SS 316-L AS PER GMP GUIDELINES

2)APPROPRIATE AND BEST QUALITY BEARINGS

3)HIGH PRECISION SPIRAL BEVEL GEARS WITH TEETH GROUND IMPORTED FROM JAPAN

ON ACCOUNT OF ACCURACY AND SPECIAL RAW MATERIAL SMALLER SIZE ENABLES COMPACT GEARBOX AND SMOOTH & NOISELESS OPERATION.

4)VITON SEALS USED

5)FOOD QUALITY GREASE USED

DELUMPER

MODEL: TECHNOCRAFT 3020

The Bevel Gearbox is used for changing the orientation of rotation by 90 Degrees.

The output is derived from combination of Motor and Worm Gearbox.

Here speed is low however Torque to be transmitted is high.

The Bevel Gearbox 1:1

The Requirement for DELUMPER is summarised as follows:

1.Right Angle Bevel Gearbox 1:1

2.Operating RPM : In the range of 30-60 RPM. Torque 500 NM TO 1000 NM.

3.Material of Construction : All the external surfaces Fabricated out of SS - 316L grade with TC

4.External shape : to be inline with GMP guidelines (e.g there should not be any external crevices. Should be smooth…so

that the product, which is pharmaceutical powder, easily slides over and falls down)

5.All external surfaces should be washable and sterilizable (by steam)

6.Exposed plastic/rubber surfaces (for example the seals) of food grade/FDA approved. Viton seals and Food quality grease used.

7.Self-sufficient in terms of lifetime lubrication

8.No oil spills/leakages